PRECISION PROFILE WIRE IN STEEL AND STAINLESS STEEL

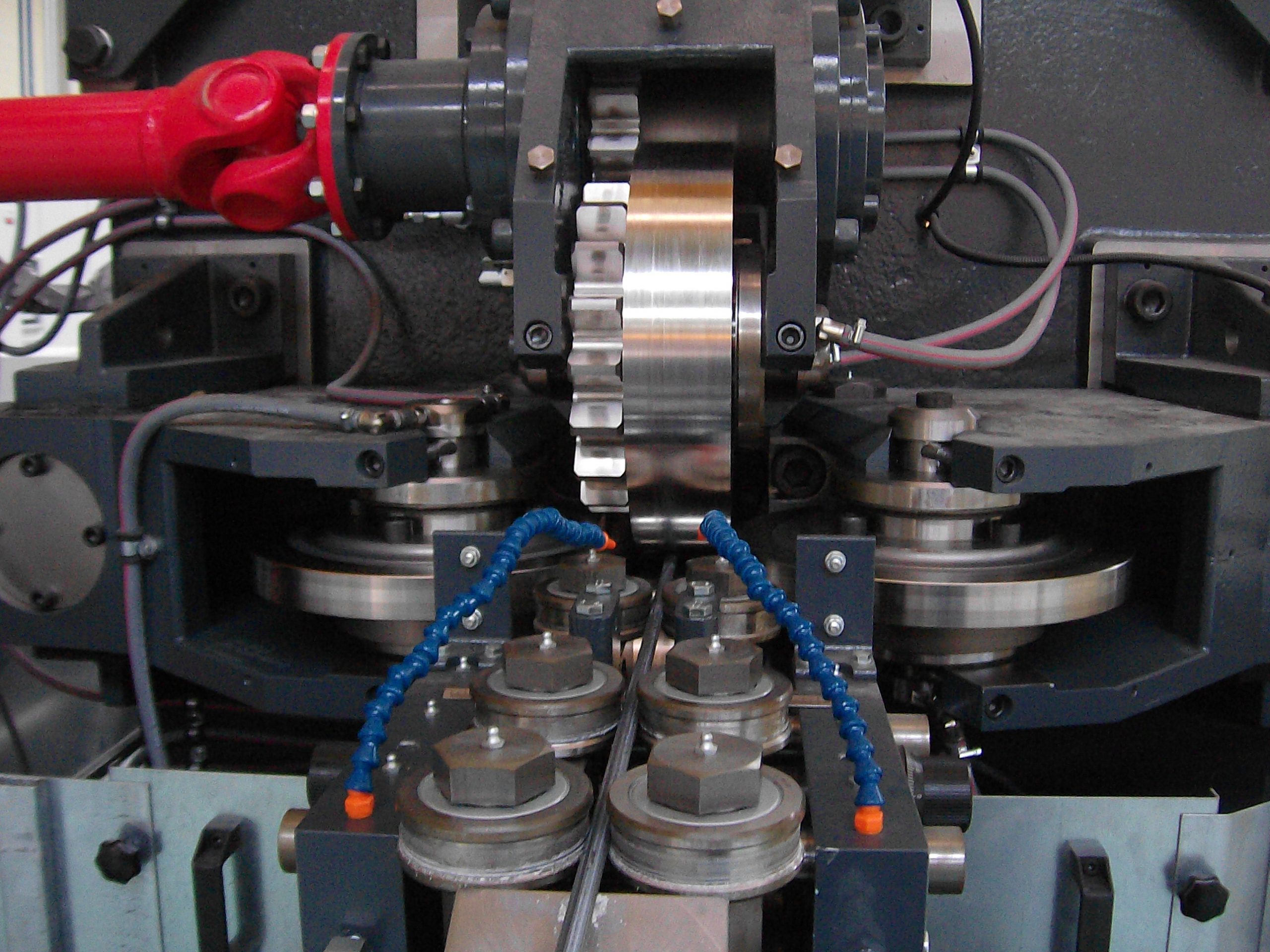

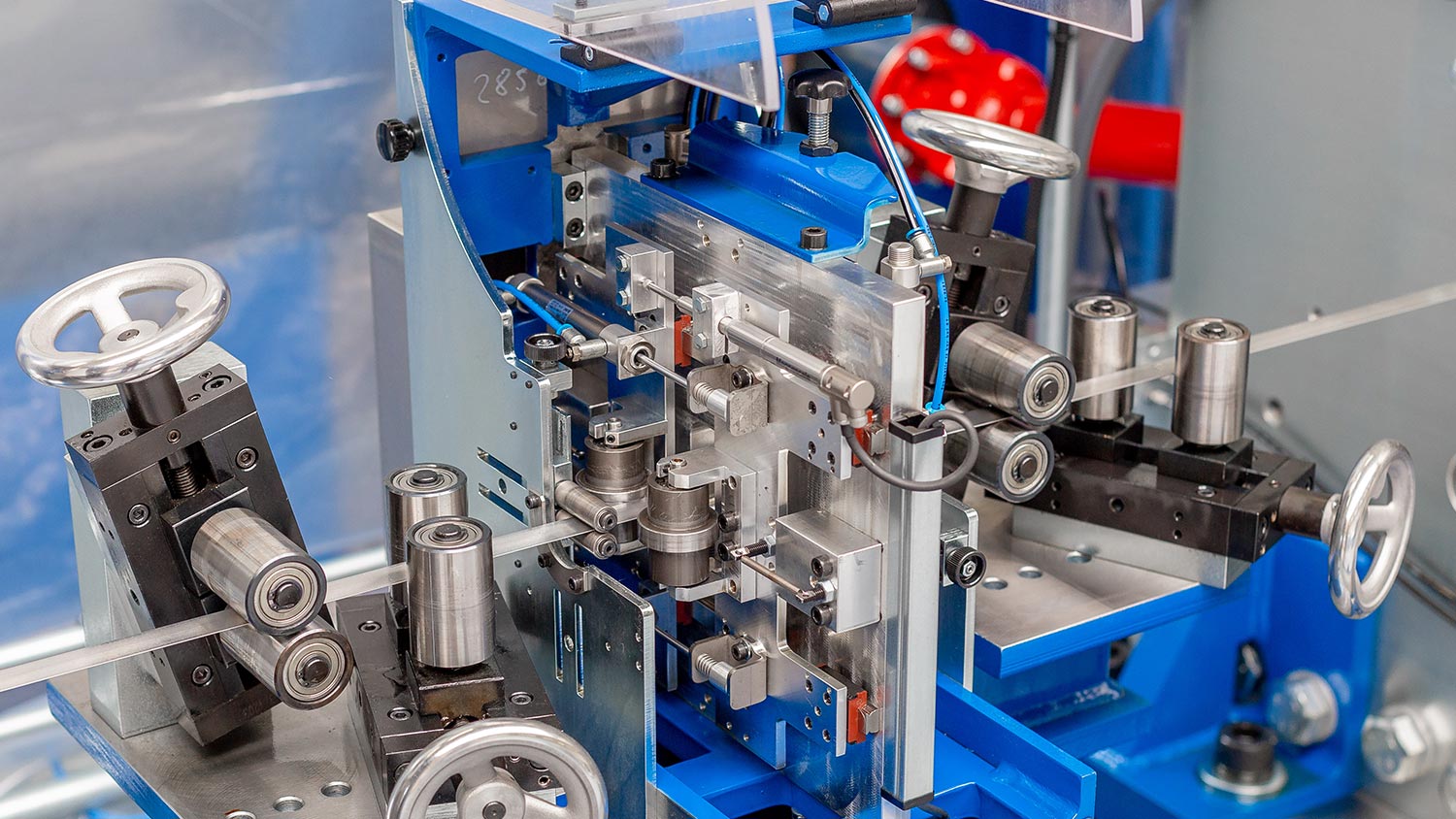

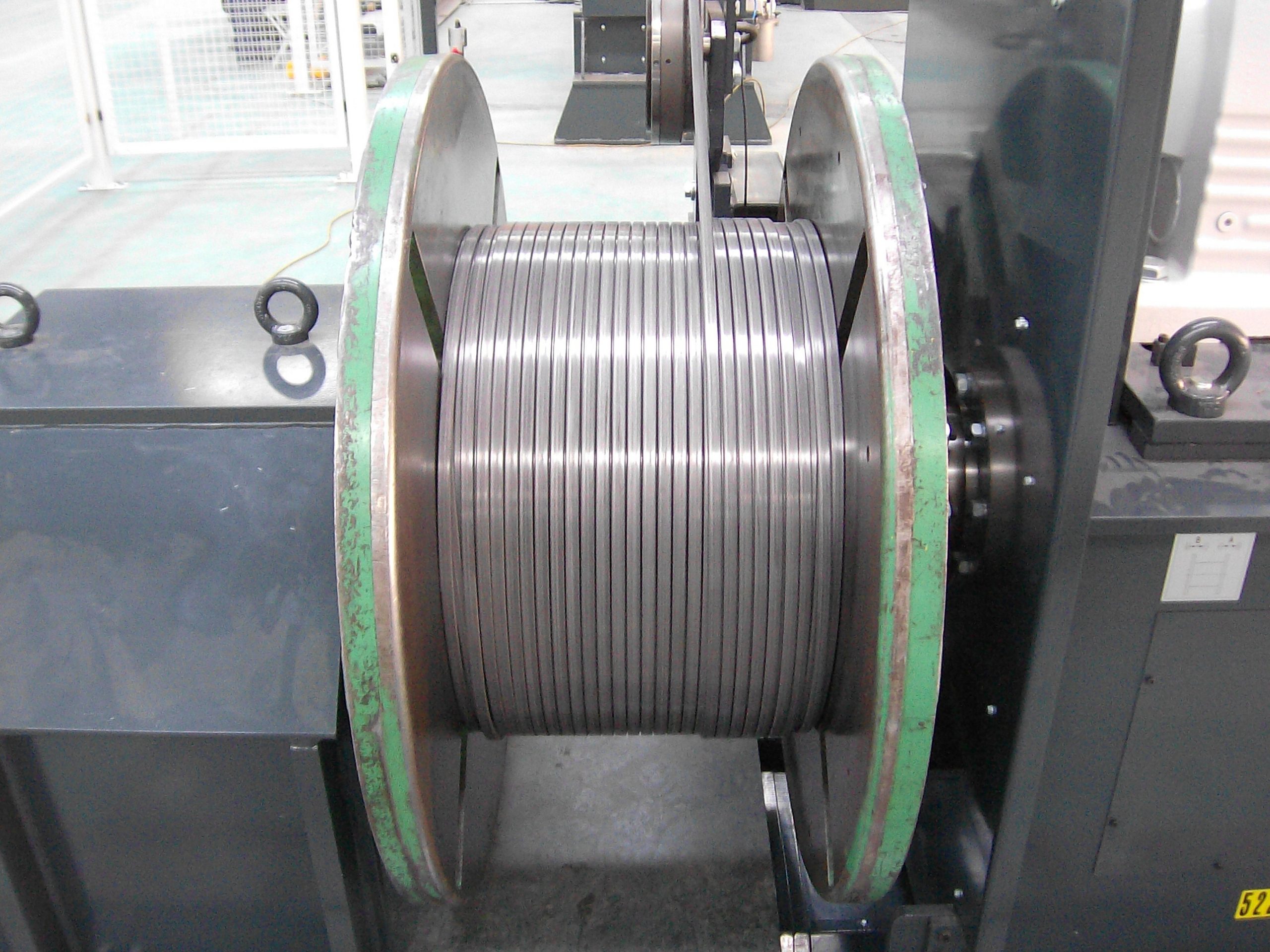

In comparison with drawing processes with profile drawing dies, the production of steel profile wires in the cold rolling process is more cost efficient. At the same time qualitatively better results are achieved.

Rolling can produce shaped cross sections which are close to the final product. A final processing step is often unnecessary. Examples are profile wires for piston rings, valve collets, circlips, bolts for CVT chains, steel cables, textile cardings and gap filters.