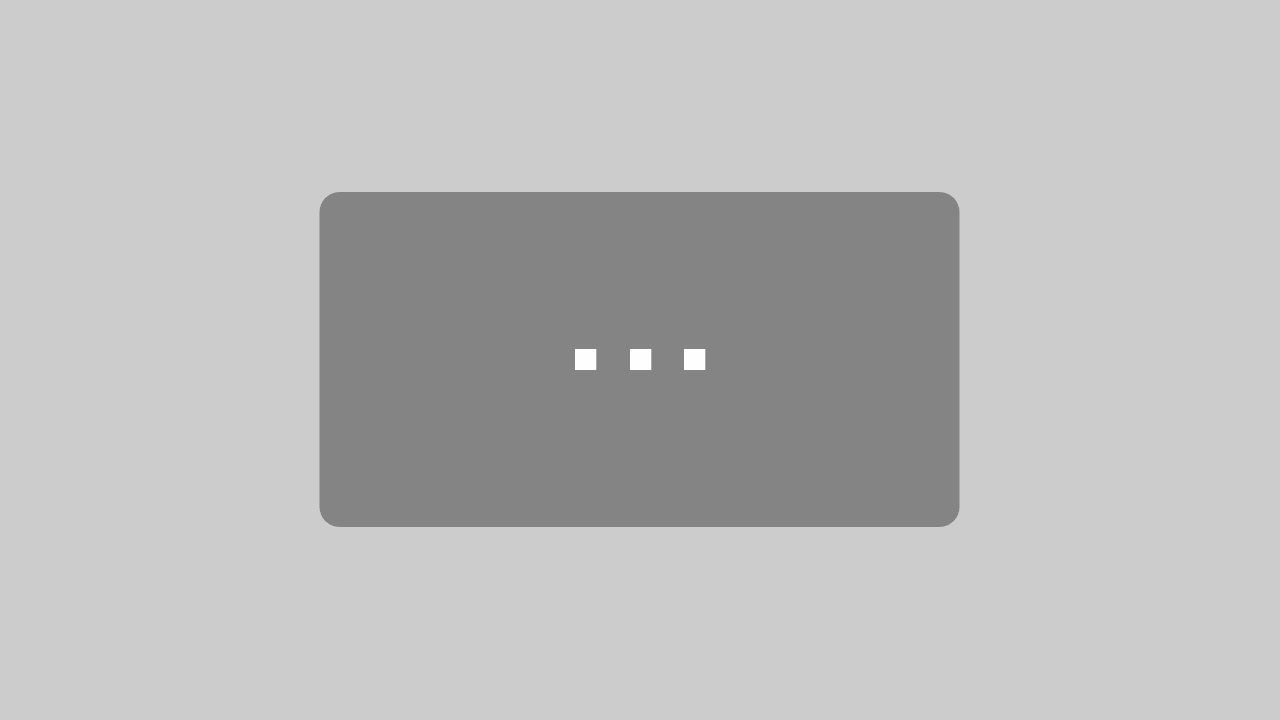

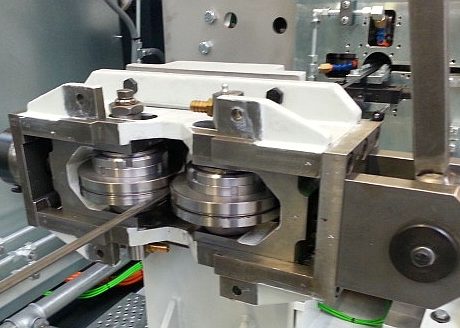

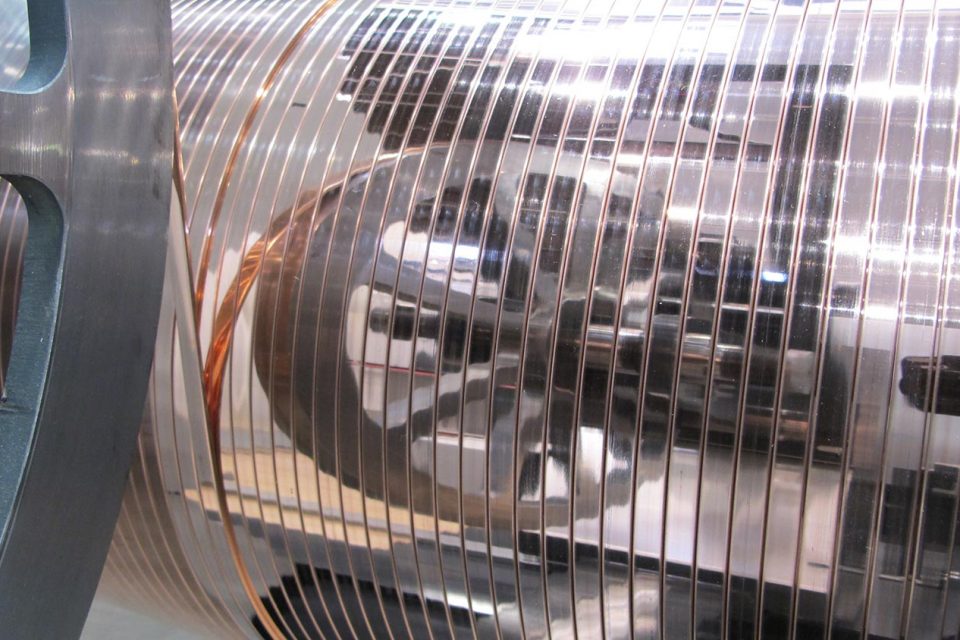

Complete production lines for your products

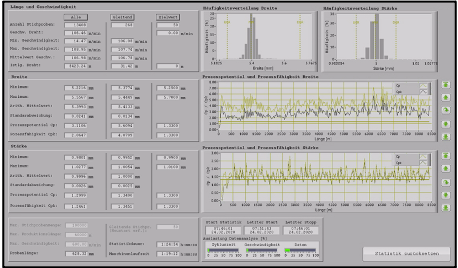

From our modular component range, we will build a production line optimally matching your requirements. Here, we perceive ourselves as a system supplier designing, constructing, building, delivering and commissioning your system.

We take full responsibility for our system producing your products in the quantity and quality that you require.