WST | Universal

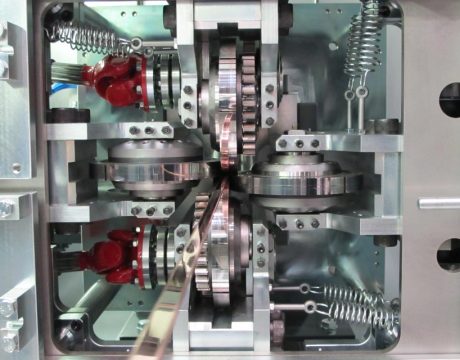

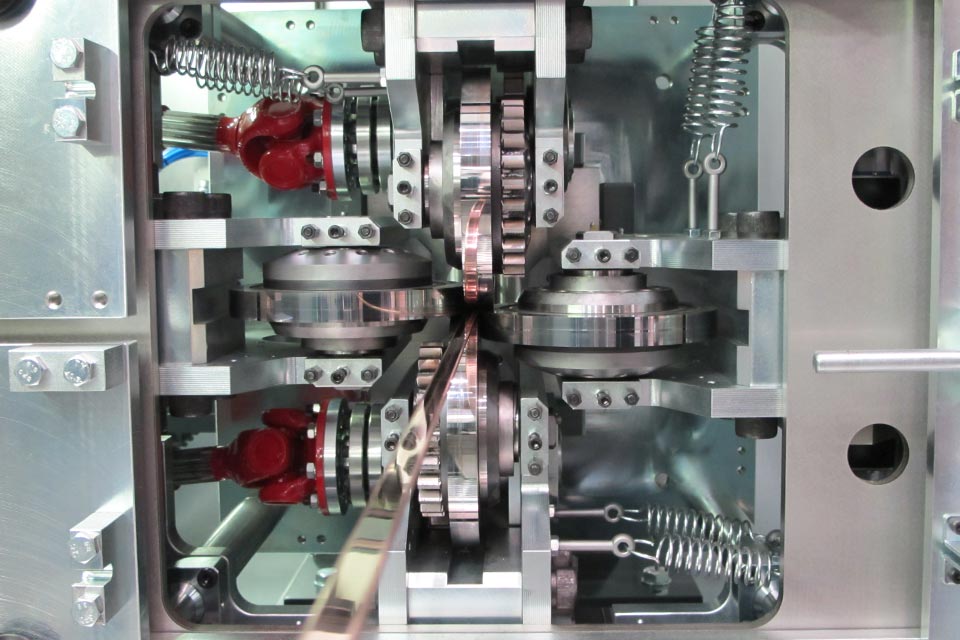

Type WST | Universal profile rolling mill

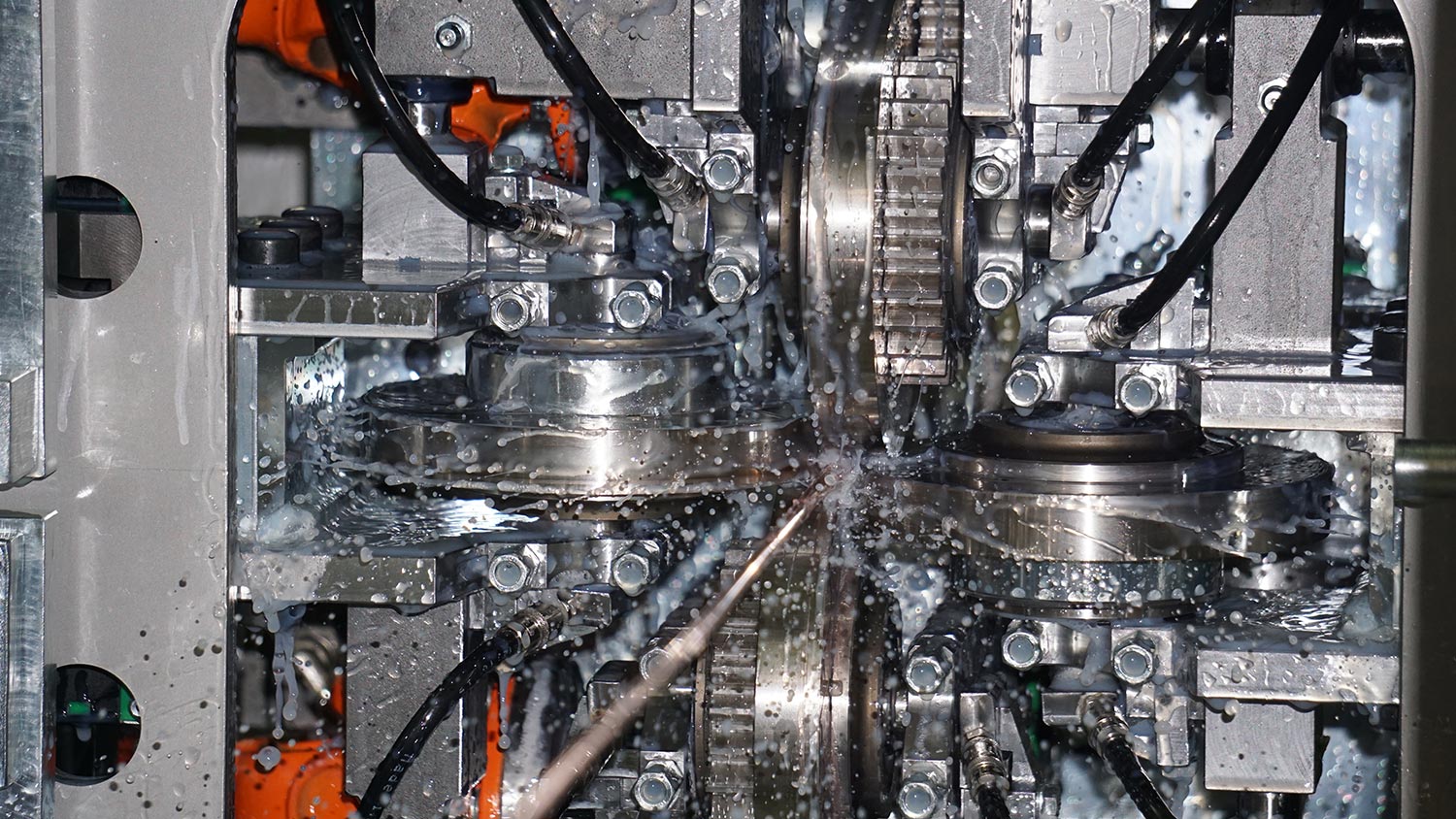

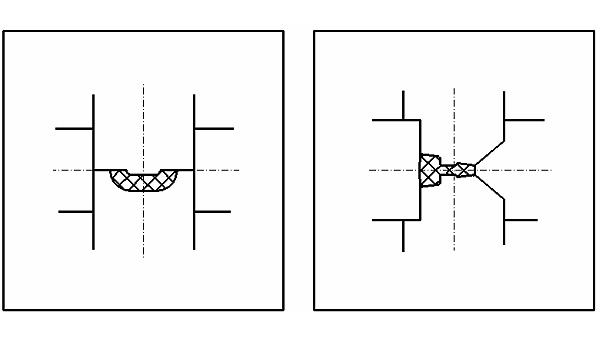

The special feature of the WST profile rolling mill in comparison with the WSN and WN types is the additional adjustability of the rolls in the axial direction. Each roll can thus be adjusted radially and axially.

This special flexibility allows the WST type profile rolling mill to produce wire with a rectangular or square cross section using only one standardized set of rolls. This saves the time, the cost and the labour required to change the rolls for the desired wire profile. All dimensions of wire can be produced immediately.

The WST type rolling mills have extremely low maintenance requirements. All components are protected from corrosion by galvanization.

Application examples

Basic model

- Undriven rolls

- Manual roll positioning

- Radial and axial roll motion mechanically coupled

NC positioning of the rolls

- Specification of the wire dimension on the touch panel

- 8-axis servomotor control

- Fully automatic calibration in ten minutes

- Roll force measurement for protection of machine

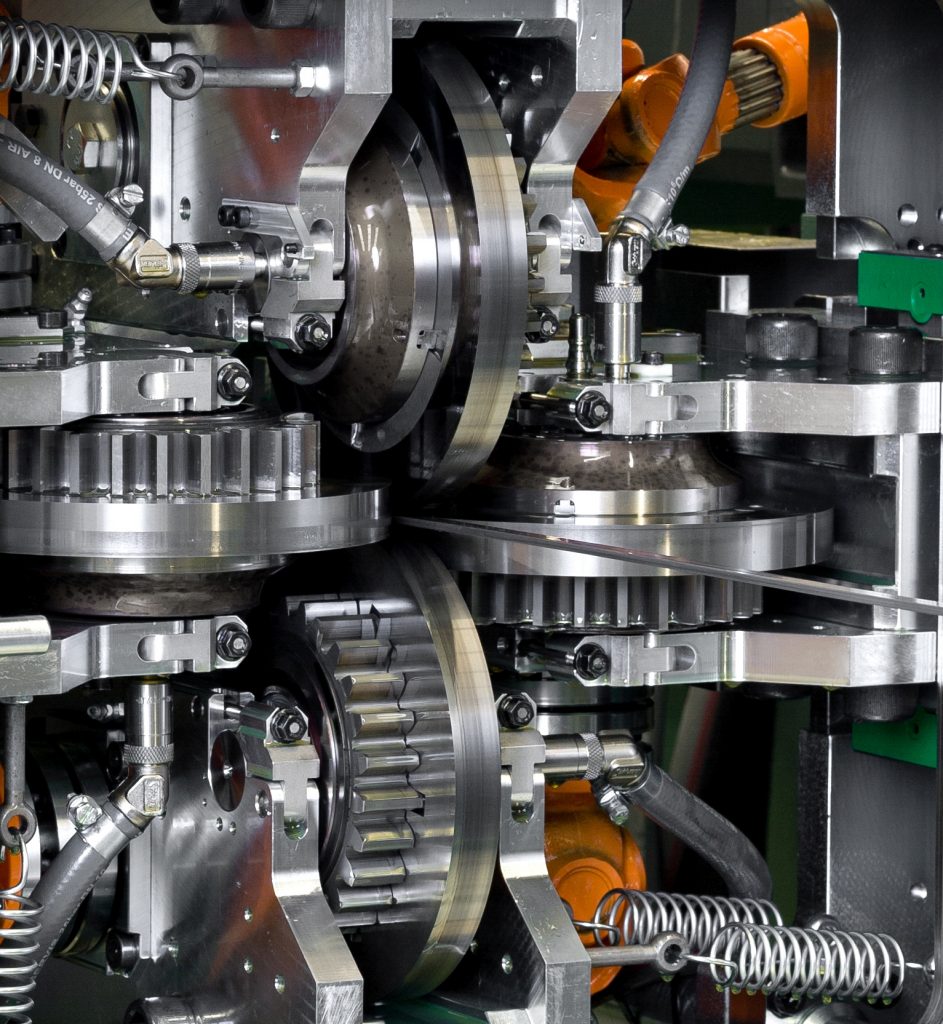

Roll drive

- Selective drive of one, two, three or four rolls with separate motors, drive shafts and geared drives

- Electronic load distribution for simultaneous use of rolls with different diameters

Cable calibration

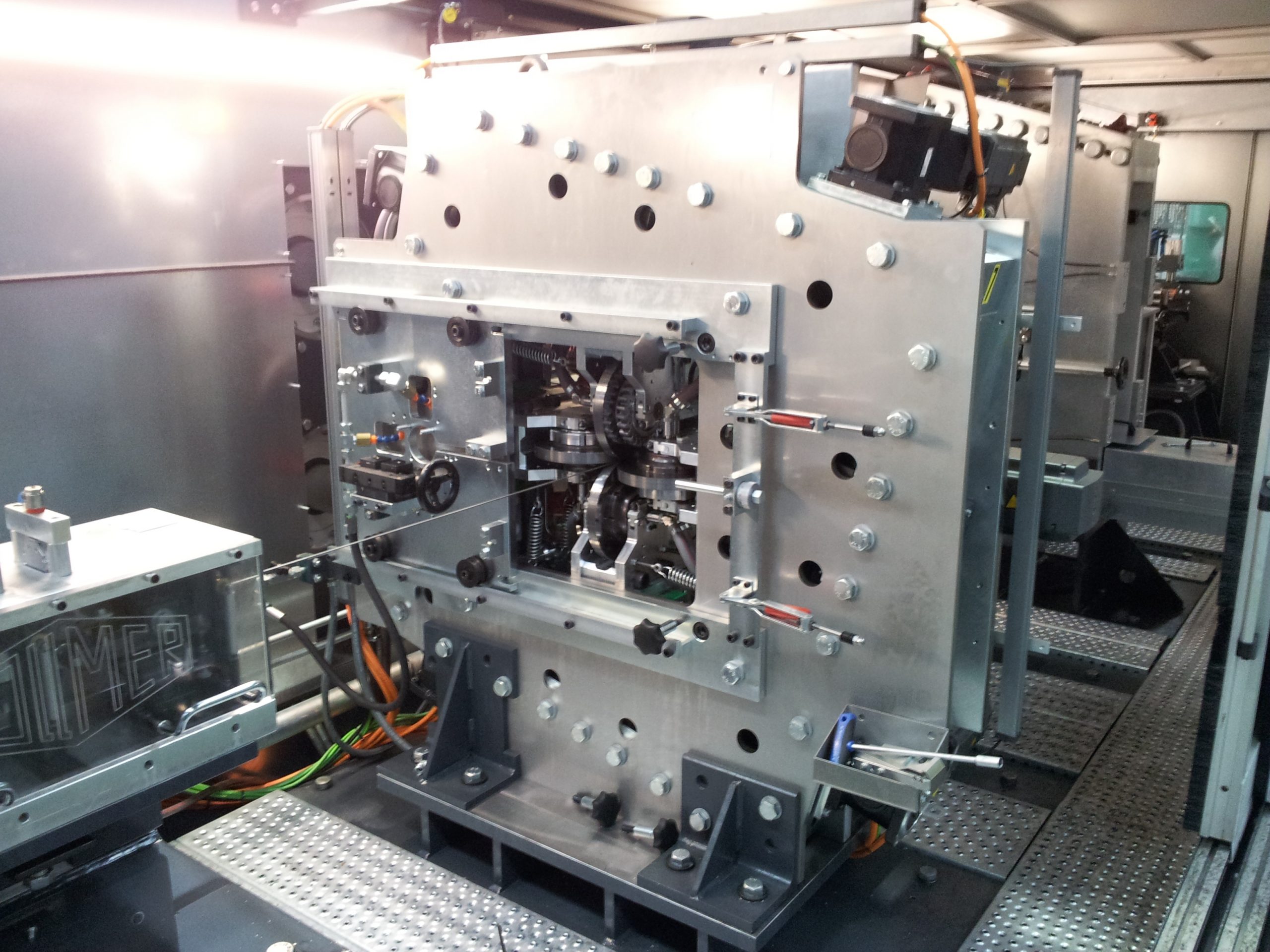

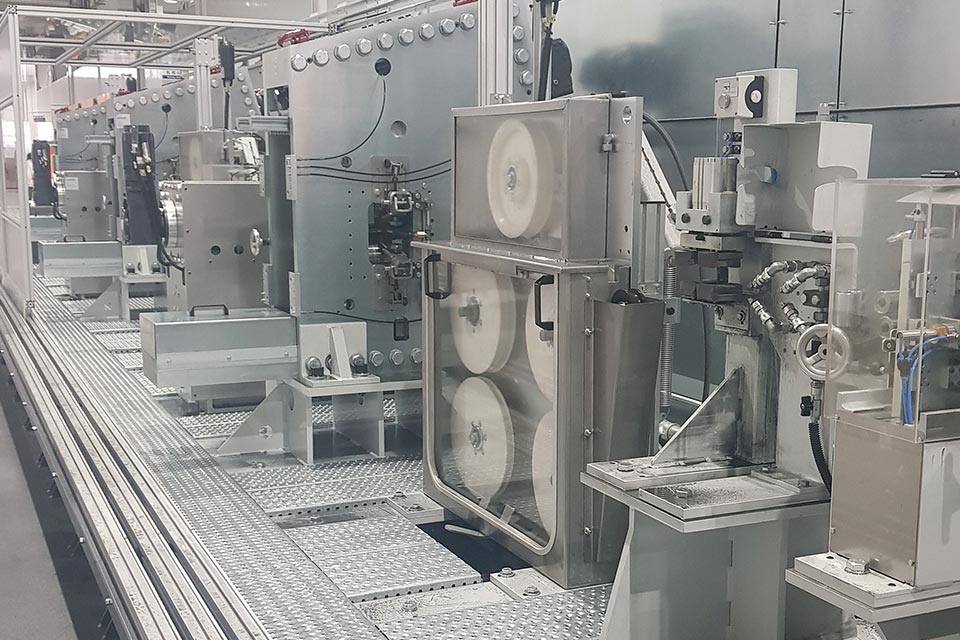

Rolling mill integrated in production line for rectangular multi-wire conductor consisting of:

- Stranding machine

- Rolling mill type WST175-Mo

- Caterpillar haul-off

- Paper insulation machine

- Winding machine

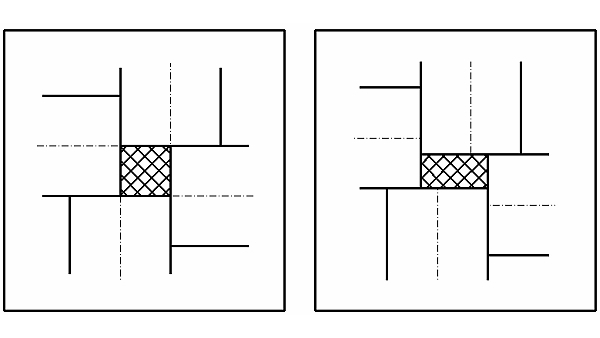

Square and rectangular profiles

- All wire dimensions with a single set of rolls

- Specification of the wire dimension on the touch panel

Special profiles

- Roll set specially shaped for the particular wire profile

- Automatic calibration

Technical data

| Type | Roll diameter [mm] | max. roll width [mm] | max. rolling force [kN] |

| WST 112 | 106–120 | 20 | 40 |

| WST 175 | 170–190 | 32 | 112 |

| WST 225 | 220-240 | 40 | 180 |

| WST 280 | 270–300 | 50 | 300 |

| WST 350 | 350–380 | 60 | 500 |

Customer specific variations are possible. Example: Further use of existing rolls, etc.

Accessories

- Central lubrication of the roll bearings with grease or oil

- Various designs of wire guides

- Roll mounting devices and bearings

- Roll rings in various materials (steel, tungsten carbide, …)