WSR | Flat Wire

Type WSR | Precision 2-high rolling mill

The 2-high rolling mills of the WSR type differ from the usual 2-high machines available for wire in their higher stiffness and the resultant higher precision of the flat wire produced.

Unique to the WSR FUHR rolling mills is the option of oscillating the rolls continuously crosswise to the wire. This obviates the otherwise usual changing of the track and the working life of the rolls increases many times. The degree of utilization increases.

Rolling mills of WSR type have extremely low maintenance requirements. All components are protected from corrosion by galvanization.

Application Examples

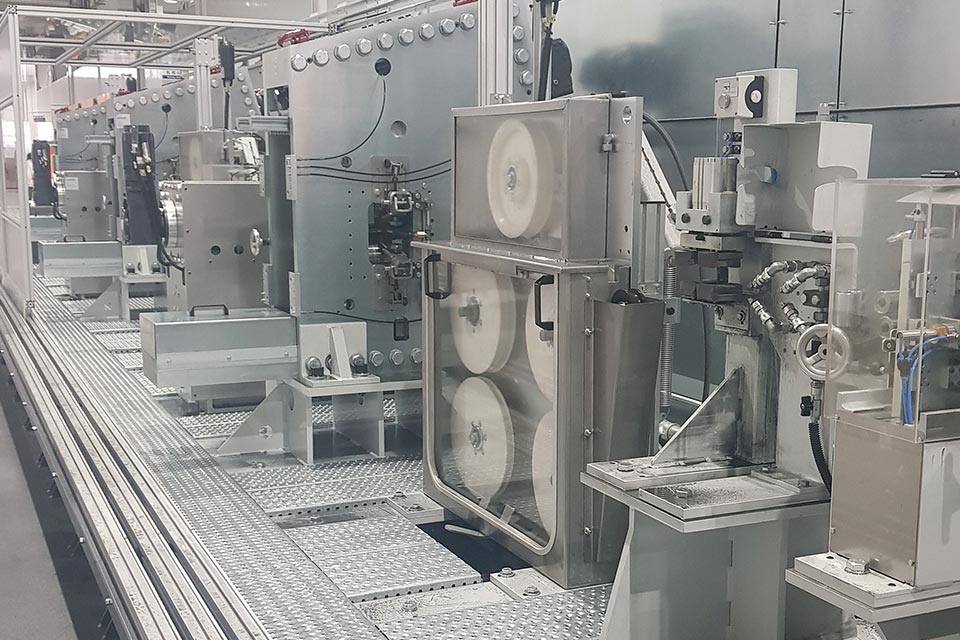

Automatic roll change

From design size WSR140 upwards the roll change is automated.

- Change of a complete set of rolls in 15 to 60 minutes depending on size.

- Best possible ergonomics

- No danger of accidents

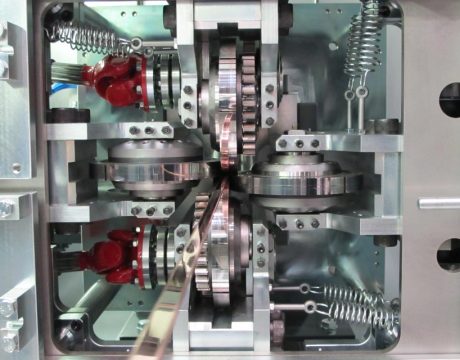

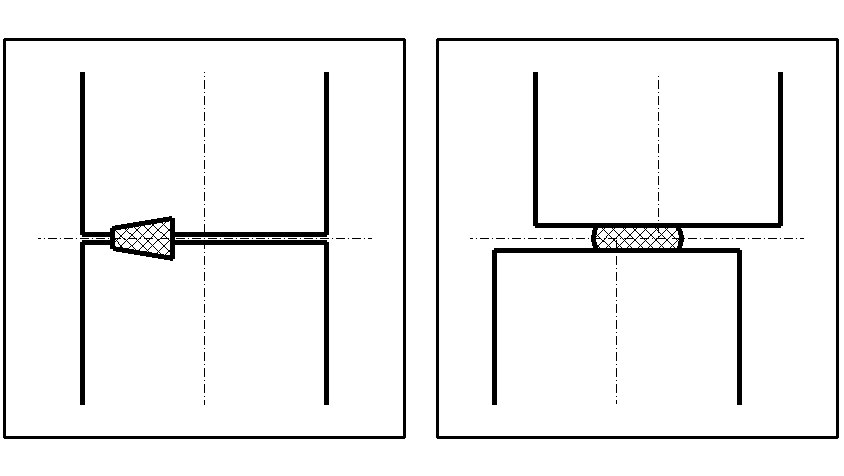

Schematic representation of the rollers

Profile and flat wires

By the use of profiled rolls, the WSR 2-high mill can also be used to produce profiled wire. The two rolls are aligned precisely to each other by the use of axial roll adjustment by servomotors.

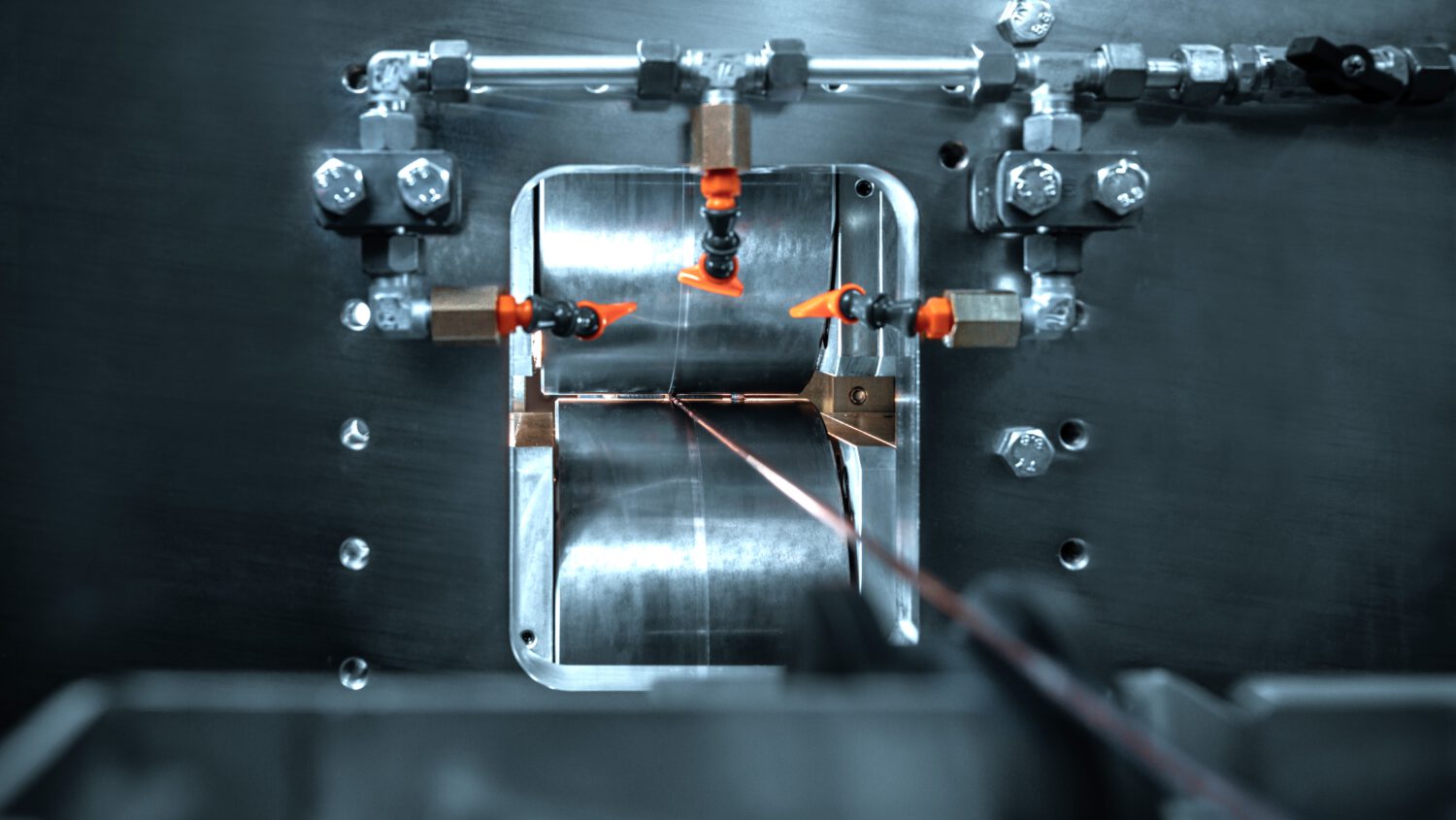

Plain rolls are used to produce flat wire. Here the rolls oscillate across the wire to avoid track marks on the roll surfaces.

Technical data

| Type | Roll diameter [mm] | max. roll width [mm] | max. rolling force [kN] |

| WSR 112L | 108–120 | 60 | 75 |

| WSR 140XL | 145–160 | 80 | 189 |

| WSR 225 | 200–220 | 140 | 540 |

| WSR 225XL | 240–260 | 140 | 540 |

| WSR 280 | 270–300 | 200 | 900 |

| WSR 350XL | 370–400 | 220 | 1300 |

Customer specific variations are possible. Example: Further use of existing rolls etc.

Accessories:

- Central lubrication of the roller bearings with grease or oil

- Various designs of wire guides

- Rolls in various materials (steel, tungsten carbide, …)

- Roll ring systems for economic production of profile wires