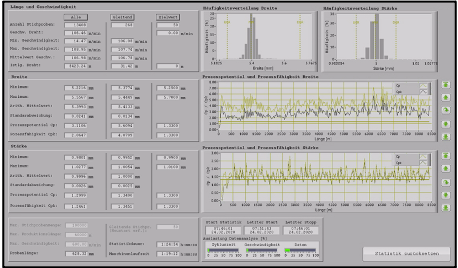

Until recently, measurement systems for measuring the quality of products during the process were used almost exclusively for process control. Process variables were measured, then compared with target values and the settings of the production plant were optimised with the deviations determined.

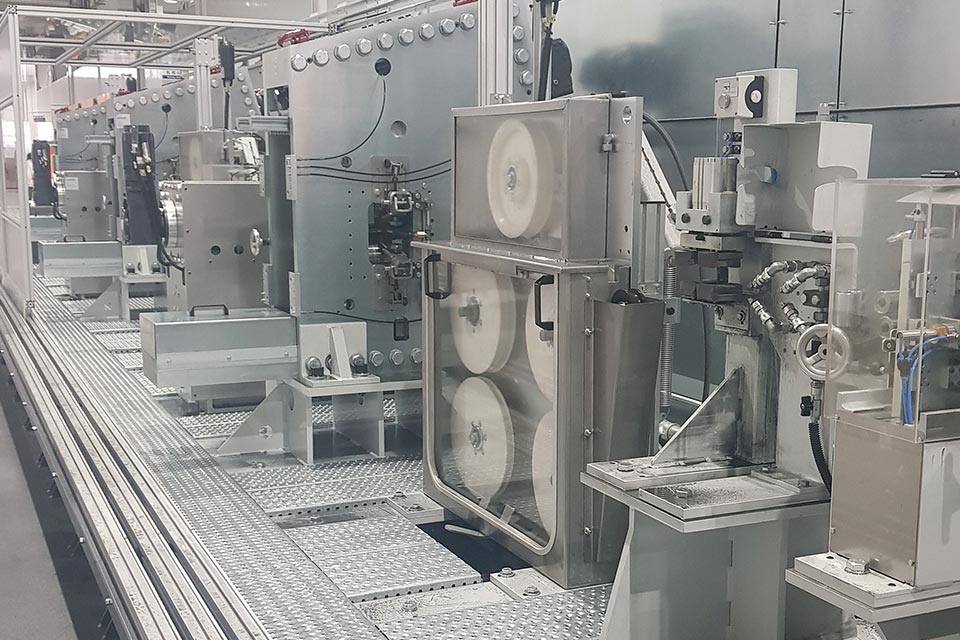

Conventional laser shadow measurement systems, as typically used in the drawing of round wires, have not proven themselves in profile rolling plants. For one thing, even a slight tilting of the wire changes the size of the shadow. On the other hand, laser systems cannot be used permanently in the wet area of the pre-rolling stages.

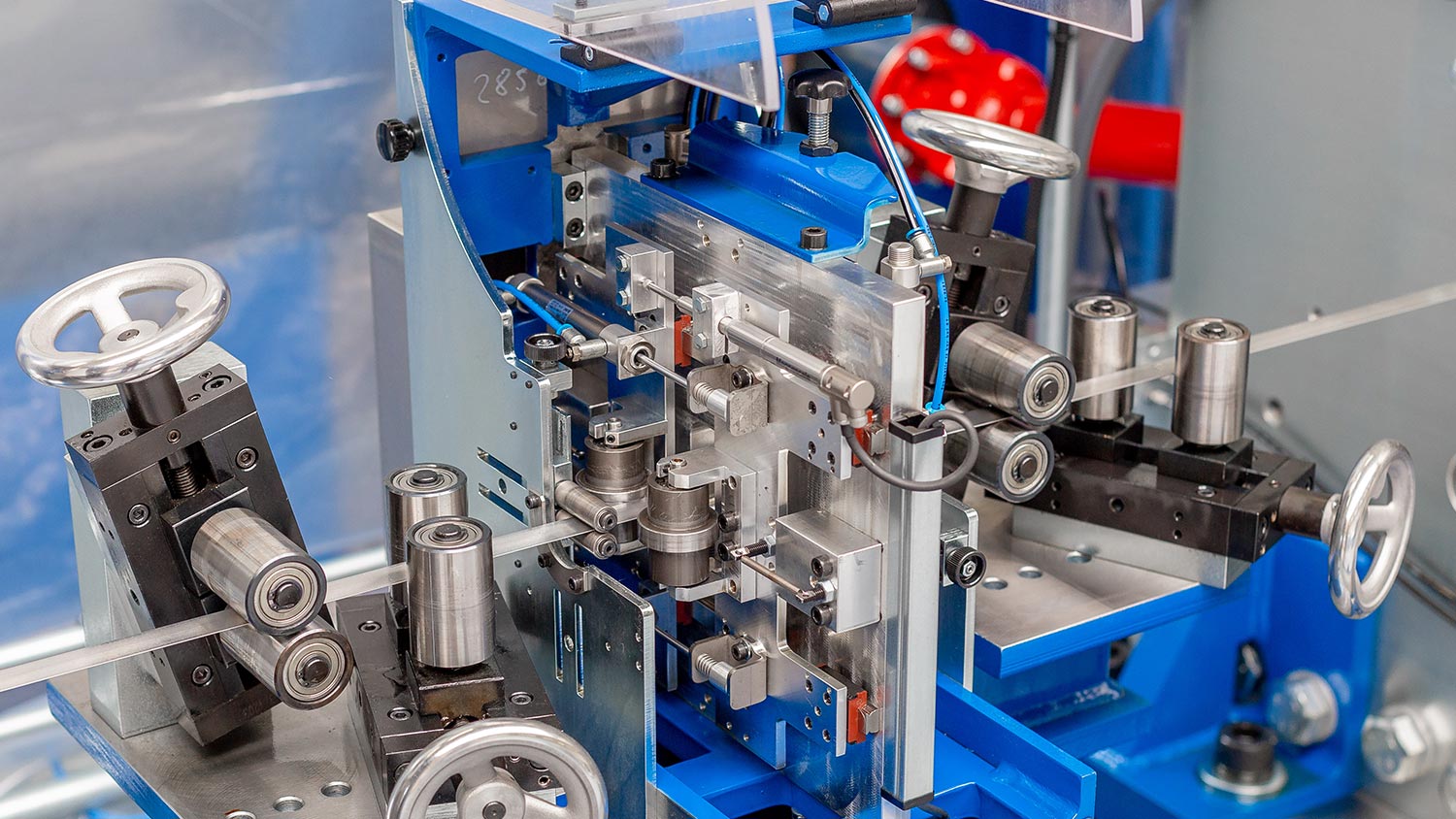

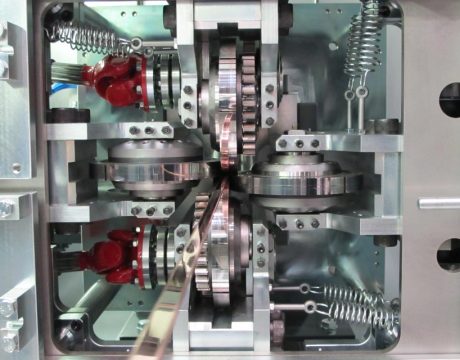

FUHR therefore relies on tactile measuring systems in which the wire is scanned with diamond-tipped, high-resolution displacement measuring systems. Alternatively, instead of diamond pins, pin rollers are available that are specially adapted to the wire geometry.

Measurement systems

by FUHR