News

Experience Excellence, No Strings Attached: Rent the FUHR IPU320!

Don’t just take our word for it—test the future of Hair-pin wire production! The FUHR IPU320 is now available for hassle-free rental, empowering you to try, test, and transform your operations without the commitment of purchasing.

Test Before You Invest: Uncertain if it’s the perfect fit? Rent the IPU320 to experience its unmatched precision and versatility firsthand. Put it through its paces and ensure it aligns seamlessly with your production needs.

Tailored for Any demand: High or low, our rental service caters to your volume requirements. For lower product volumes or intermittent projects, renting the IPU320 offers the same cutting-edge technology without the burden of ownership.

Minimize Risk, Maximize Rewards: Minimize financial risk by renting. With no heavy investment upfront, you gain access to top-tier wire inline profiling capabilities while preserving your capital for other business needs.

Flexibility at Your Fingertips: Adapt to changing demands effortlessly. Whether it’s a short-term project or a trial run, our rental options grant the flexibility to scale equipment according to your evolving business landscape.

Expert Support Included: Benefit from our expertise! Our rental service includes comprehensive support and maintenance, ensuring smooth operations throughout your rental period.

Stay Ahead of the Curve: Embrace innovation without hesitation. Renting the IPU320 ensures you’re always equipped with the latest advancements in wire processing technology.

Ready to elevate your wire processing capabilities risk-free? Contact us today to discuss flexible rental options for the FUHR IPU320 and witness how testing or renting can propel your operations to new heights!

Product of the year – CWIEME 2022

We did it!

It was the first time for us to show our new IPU320 at an exhibition. The CWIEME 2022 event was great, and we had the chance to speak with many interesting people.

We did not expect that but winning the Award for “product of the year” was also a highlight of the show. Many thanks to the CWIEME Team!

Strong partnership!

Due to the developments in the EV sector, the global demand for enamelled rectangular copper wires is increasing. We have already sold more than 30 of our IPU320 inline profiling units, which customers can use directly in line with their insulation line.

Since end of 2021, we cooperate with MAG machines GmbH in building production lines for enamelled rectangular wire. This cooperation ensures to provide the most reliable and economic machinery to our customers by focussing on each partie’s strengths.

Profile wire measurement in process

With statistics module, data export and frequency analysis

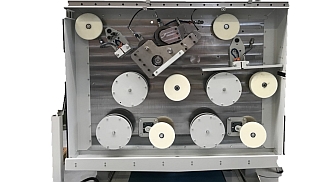

In times of Industry 4.0, measuring systems that are used exclusively for process regulation are often no longer sufficient. Rather, measurands should also be analysed and documented. For this purpose, a supplementary module can be added to tactile measuring systems with diamond tips or tracer rollers that match the profile and are used instead of conventional laser shadow measuring systems.

It is the data acquisition and evaluation system F-MAS, with which real data from two wire dimensions can be recorded and, for example, evaluated by means of diagrams, statistics or frequency distribution, so that reports can be generated. An FFT analysis for the detection of cyclical dimensional fluctuation is also integrated, which in turn supports the search for causes of quality deviations.

Enamel-insulated rectangular wire for the electric mobility

Rectangular copper wires are usually produced with drawing dies. If the bare wire is to be enamelled for use in e.g. electric motors or transformers, it is wound up and then coated in several steps with a thin layer of enamel. During the winding and unwinding of the wire, damage can occur, which can lead to insulation faults in further processing and ultimately cause the failure of the winding during operation.

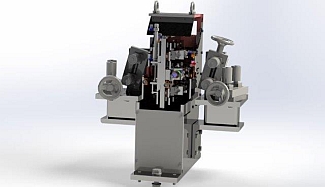

This results in the task of inline production. With the IPU320, FUHR has developed an economical inline profiling system with which the manufacturers of enamelled wire can meet the high demands of e.g. the automotive industry in terms of quality and price without having to spool the bare wire. The IPU320 combines rolling and profile drawing processes and is equipped with a closed control system, so that the compact machine can usually be retrofitted without having to adapt the existing system.

Release of Biggest Profile Rolling Machine

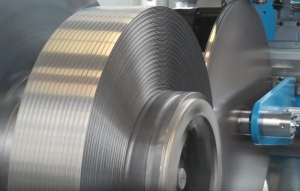

By adding the profile rolling machine WN16 FUHR has enlarged its portfolio on the upper side. The new type WN16 allows shape rolling of steel wires up to 900 mm² from round wires of maximum 40 mm diameter.

The biggest stand so far the WN14 was limited to shapes of 600 mm² from round wires of maximum 32 mm diameter.

By approaching this dimensional range, cold rolling enters application fields which have been domain of hot rolling or bar drawing. Compared to those processes cold rolling offers the best of both: Precision and productivity.

Flangeless production of coreless coils

By combining a perfect guiding system and an optimized laying software coreless coils of aluminium strip are produced flangeless at speeds up to 1000 m/min.

Cold rolling of linear guides replaces conventional production process

Profiled rail guides are available in different designs and sizes. Guides with rails from 15 to 25 mm height have a large market share. For this important market segment FUHR has developed cold rolling mills, which produce the rails from round wire feedstock.